Plant Facility

Plant Facility

▼

- Home

- Plant Facility

- Electro-deposition coating

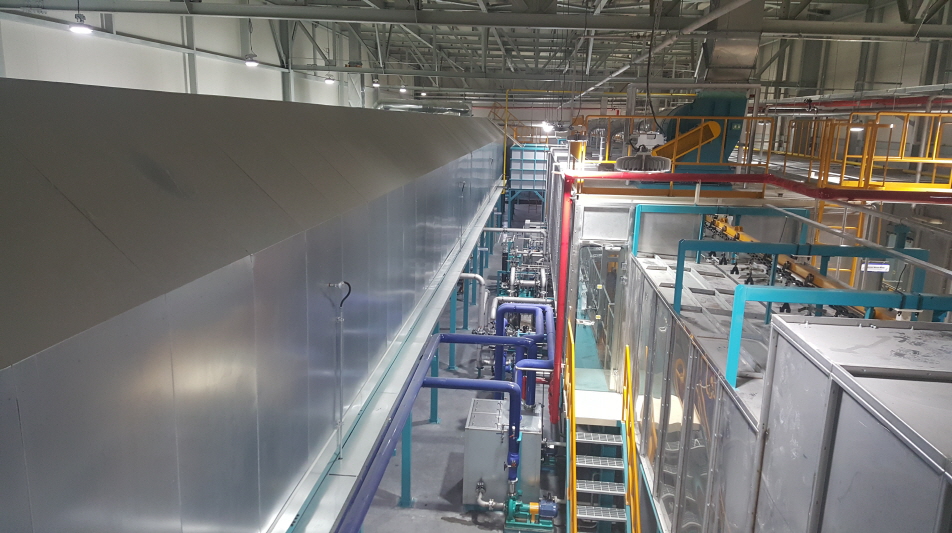

Electro-deposition coating

What is electro-deposition coating?

A coating method for immerse coated material into water soluble paint through adding electric charge onto particle of paint. This is to deposit coated material into water soluble electro deposition coating to obtain coating electrically by using direct current between opposite poles The main characteristics of electro-deposition coating are as follows.

Firstly, such coating enables automation system therefore save energy for coating from pre-processing to corrosion painting.

Secondly, paint film sizes are balanced by controlling quantity of electricity (voltage).

Thirdly, coating is balanced that paint film is equally generated on the areas in which operator cannot treat easily or pain cannot be put well therefore corrosion resistance is improved.

Fourthly, appearance of paint film is clean. The amount of petrol in paint film generated after electro deposition is very little therefore PINHOLE and SAGGING which are generated in the other paint occur rarely, short time is required for setting direct heated drying (forced circulation) can be performed within short time.

Fifthly, this paint causes low level of contamination. As the collection rate is high and this paint is solvent based one therefore wastewater can be disposed therefore is good for environment.

Type of electro-deposition facility

Electro-deposition facility can be classified into Anionic and Cationic ones.

* Anionic electro deposition coating : This method is called anion electro-deposition coating as well which is performed by running cationic through coated material.

* Cationic electro deposition coating : This method is also called cation electro deposition coating which is performed by running anionic through coated mateiral.

Performance

|

|

|||||||