Automation Facility

Automation Facility

▼

- Home

- Automation Facility

- BELT C/V

BELT C/V

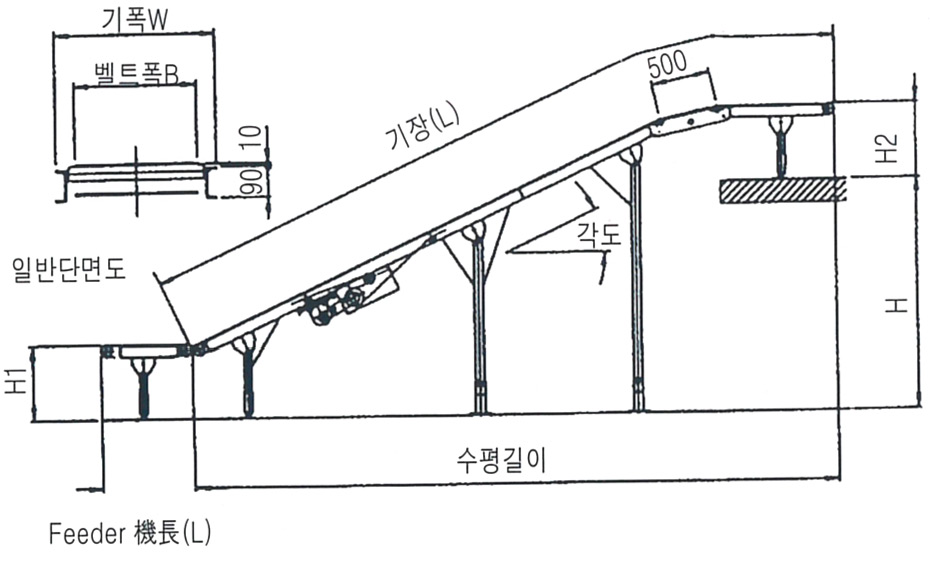

BELT SLOP (HORIZONTAL) CONVEYOR

Belt conveyor is the mostly-used one among the others that it can transport and load products located on any horizontal or sloped places. The installation cost is low and this equipment can transport large amounts of materials within short time The transportation materials are generally coal, cement, koukous, electric device, sand and pebble.

BELT SLOP (HORIZONTAL) CONVEYOR

MEASUREMENT

| Belt width(R) | width(W) | Motor frame Take up frame tail max width |

|---|---|---|

| 300 | 410 | 101.6 |

| 400 | 510 | 35.7 |

| 500 | 610 | 57 |

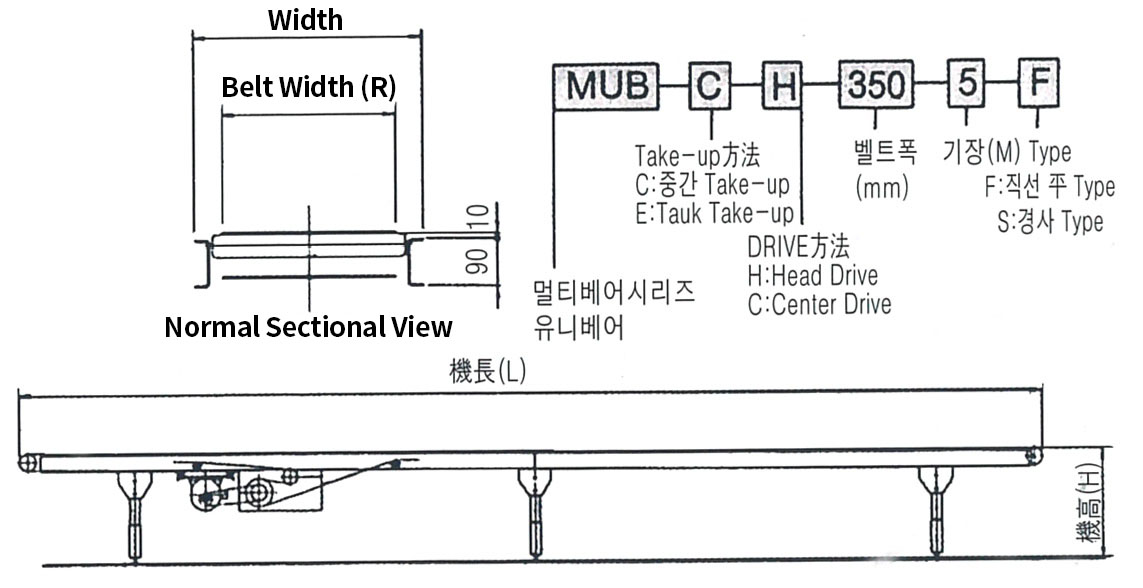

HORIZONTAL BELT CONVEYOR

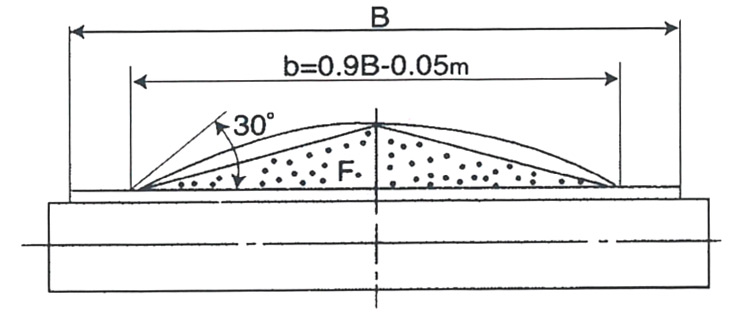

HORIZONTAL BELT CONVEYOR THEORETICAL CARRYING CAPACITY

- The carrying capacity of horizontal bel conveyor is calculated through the following formula.

Qm=F1×3600γ=240γ(0.9B-0.05)2

- Theoretical carrying capacity when belt speed is γ=1m/sec

Theoretical carrying capacity of horizontal belt conveyor is m3/h

| Classification | Belt Width Bm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 400 | 500 | 650 | 800 | 1200 | 1200 | 1400 | 1600 | 1800 | 2000 | |

| Qm | 23 | 38 | 69 | 108 | 173 | 253 | 351 | 484 | 592 | 735 |

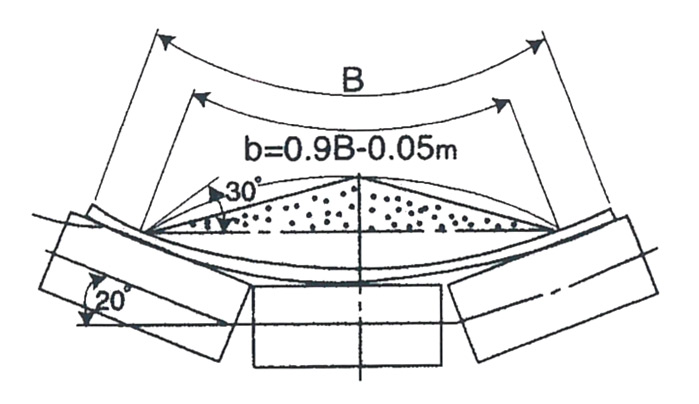

TRAP TYPE BELT CONVEYORR

Trap type belt conveyor theoretical carrying capacity

- Trap type belt conveyor theoretical carrying capacity (Qm) is calculated by using the following formula.

Qm=(F1+F2)3600γ=440γ(0.9B-0.05)2

Qm=theoretical carrying capacity m3/h, Qactual carrying capacity

F1+F2=cross sectional area of carrying material on belt

γ=Bet speed m/sec

- Theoretical carrying capacity when Belt Speed is γ=1m/sec Trap type

belt conveyor theoretical carrying capacity m3/h

| Classification | Belt Width Bm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 400 | 500 | 650 | 800 | 1200 | 1200 | 1400 | 1600 | 1800 | 2000 | |

| Qm | 42 | 70 | 126 | 197 | 318 | 467 | 645 | 850 | 1085 | 1350 |