Automation Facility

Automation Facility

▼

- Home

- Automation Facility

- Component Description&HANGER

Component Description&HANGER

Unit Arrangement Methods

DRIVE UNIT

1. Drive unit is better to be located in the highest part of the path.

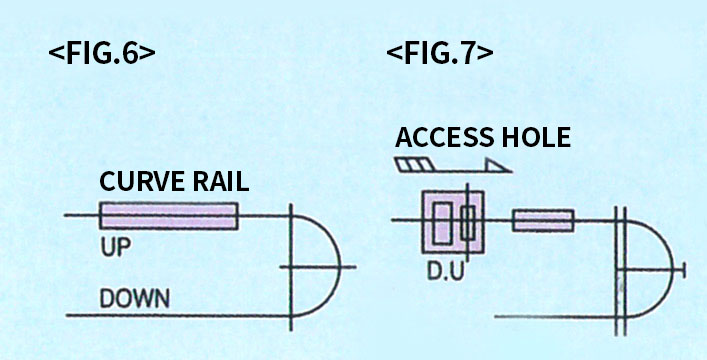

2. Regarding drive head, the down part of back tension is better to be located in right backside of the drive head (fig. 1)

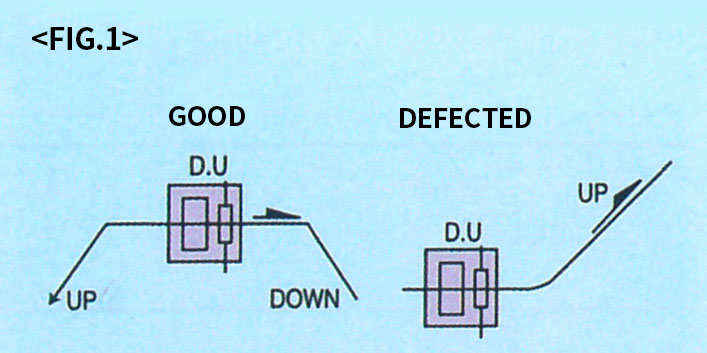

3. This should not be equipped in place in which transporting material is not stable or chain tension is not stable (fig.2)

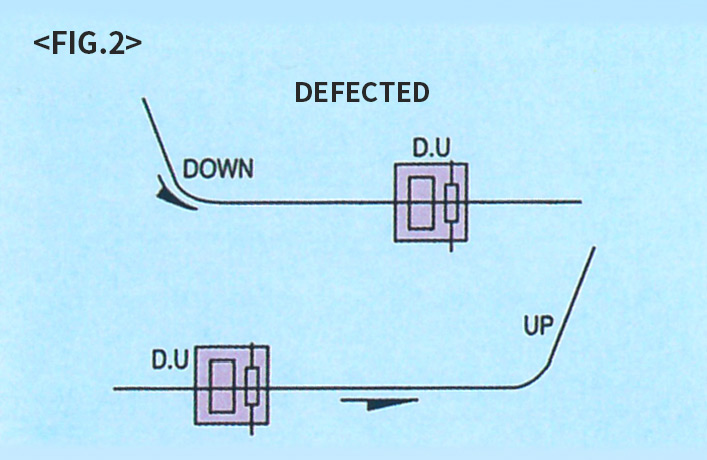

4. To reduce the final chain tension, curve rail needs to be concentrated on drive head of curve rail. Further, it needs to be installed in the backside of transporting material and it is no recommended to locate in the front (fig.3)

5. If 1 Drive "-" tension is more than 2 places, this can cause knocking therefore this state should be prevented. I.e.) tension becomes "-"if long horizontal area is at the front of down part.

TAKE UP UNIT

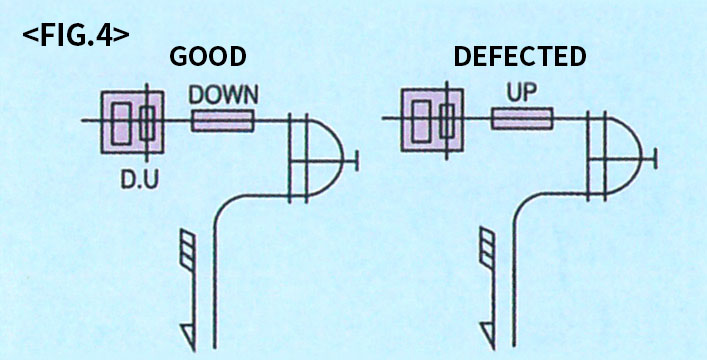

1. Take up needs to be installed on area in which chain tension is minimum which is backside of drive unit. It is not recommended to install it on up part (fig.4)

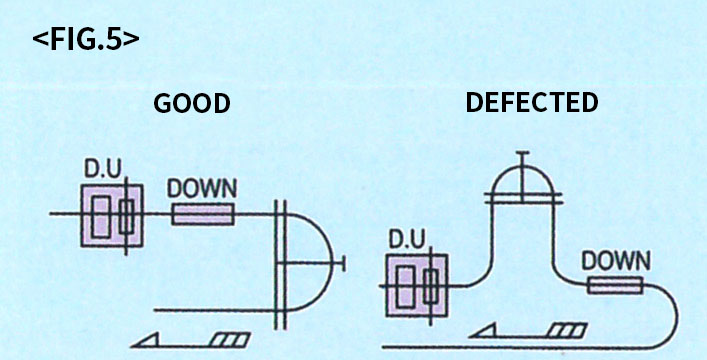

2. Even if it is at the right before drive unit, it is not recommended to install it before down part therefore it needs to be installed after down (fig.5)

3. 1) Take-up needs to be based on weight type.

2) Normal type (if there are not much of up, down and horizontal curve), spring type can be used if single drive is withing 60m.

3) However, spring type take-up needs to be installed in area of which chain allwed tension is within 1/10.

4) Weight type needs to be used for multi-driver (more than singer driver) and 1D. U1T. U needs to be installed.

5) Weight type needs to be used for expansion of chain if it passes crying furnace and on the place which is affected by temperature largely.

CURVE RAIL

1. Curve-connected rail should be inserted into the area in which horizontal curve rail and up. down curve are connected to prevent torsion of chain.

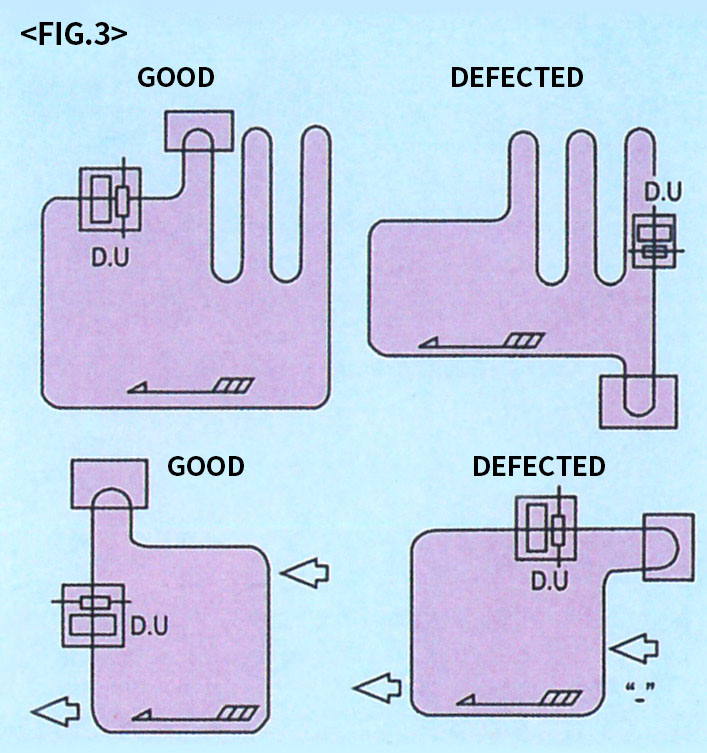

2. There needs to roller which is more than 1 pitch for running chain. (fig. 6)

Access Hole

1. Access hole s used for repairing and inspection on chain together therefore needs to be installed by one every 20-60m at the most top place of the path.

2. The equipment needs to be installed right after the Drive Unit or right before and after take up unit. (fig.7)

Fueling Device

1. Fueling device needs to be used to extend the durability of chain and roller.

2. Oil needs to be supplied to entire lines.

3. The device needs to be installed on exit of equipment such as drying furnace. However, trouble can occur on product (transporting material) therefore it can be installed between lower part and entrance of the equipment.

4. However, it can be installed on exit of the equipment if there is no product trouble.