Automation Facility

Automation Facility

▼

- Home

- Automation Facility

- BELT C/V

BELT C/V

BUCKET ELEVATOR, SCREW CONVEYOR

BUCKET ELEVATOR

Usage and Feature

- Transporting to high place

- Dust does not occur as it is completely sealed

- Uses small space

- Mainly used for silo tank for grain and feeds. Further, this is used connecting to screw conveyor

Centrifuge emission type

Increases the chain speed for carrying materials in backet which has been put into unit and multi-layered chain for emission by using centrifugal force. The costs are lower than those of the other types but operation costs are hight. Standard speed, carrying capacity.

Complete emission type

Puts bucket into multi-layered chain continuously for processing carrying material in bucket and backside of bucket as the front part of the shule. This is used for emission that low speed operatino is possible and can be used on slop area.

Derived Release Type

Release bucket continuously into multi-layered chain. This is a type for complete emission of carrying materials in bucket by transforming to snap wheel at shule part. This is operated with low speed and performs complete emission.

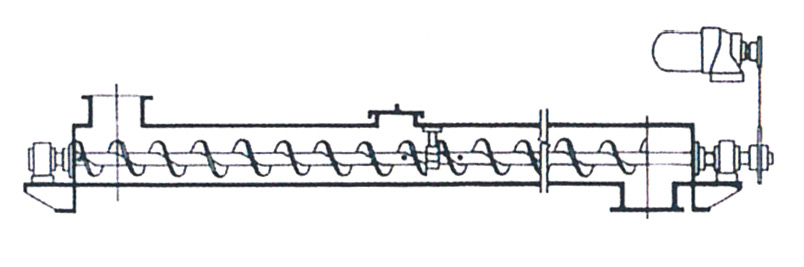

SCREW CONVEYOR

Usage and Feature

- Heat and cooling are appropriate for transportation.

- Feeding entrance and outlet can be installed randomly.

- Dust does not occur by complete sealing.

- Balance carrying capacity.

- Transport, fine powders such as grain, feed, cement and coal powder.

specifications

| Size of each unit | 軸徑/直徑 | 澐搬物의 粒度크기 | 가볍고 부드러운 (0物) | 무겁고 약간 마모성이 있을것 | |||||

|---|---|---|---|---|---|---|---|---|---|

| -mm- UNIFORMITY OF OFGRIN | -mm- MAXIMUM MASS | -mm- MAXIMUM MASS | RPM | -m2/h COANTITY TRANSMITTED | -mm- MAXIMUM MASS | RPM | -m2/h COANTITY TRANSMITTED | ||

| 150 | 40 | 15 | 40 | 2.3 | 165 | 9 | 3.2 | 100 | 5 |

| 200 | 40 | 20 | 60 | 2.3 | 175 | 30 | 3.2 | 95 | 17 |

| 250 | 50 | 22 | 65 | 2.3 | 160 | 40 | 4.5 | 85 | 36 |

| 300 | 60 | 25 | 75 | 2.3 | 150 | 65 | 4.5 | 85 | 36 |

| 350 | 75 | 30 | 90 | 3.2 | 150 | 100 | 4.5 | 80 | 55 |

| 400 | 75 | 35 | 100 | 3.2 | 150 | 155 | 6 | 65 | 77 |

| 450 | 75 | 40 | 115 | 4.5 | 130 | 190 | 6 | 65 | 95 |

| 500 | 90 | 45 | 125 | 4.5 | 115 | 225 | 6 | 60 | 115 |

| 600 | 100 | 50 | 150 | 6 | 100 | 345 | 9 | 50 | 170 |